Lisker Barn (10)

photo credit: June Pedretti

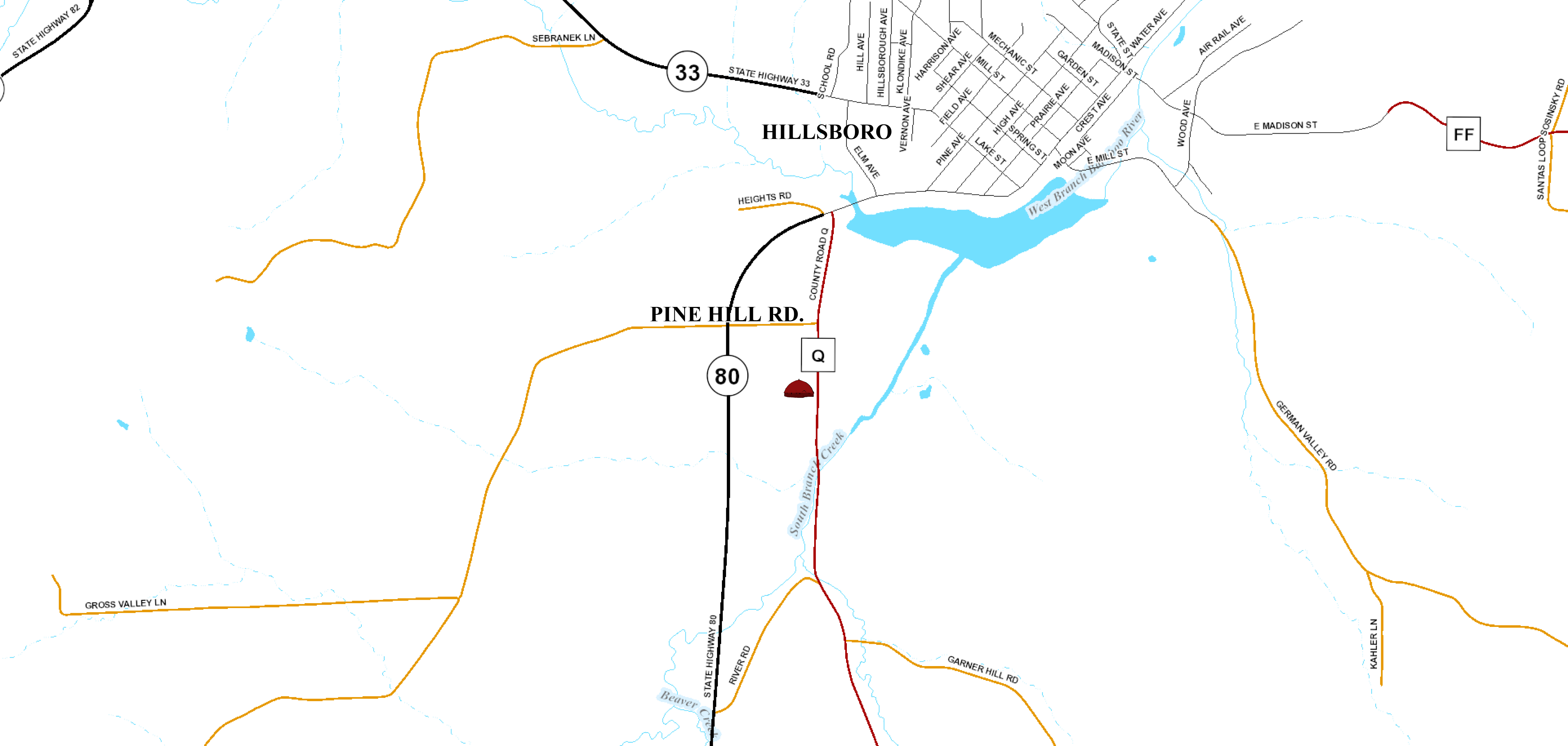

Frank Lisker and his sons, Joseph and Adolph built the Lisker barn in 1910 with help from Frank Jeffek, Frank Sladek and George Abbot. Albert Sterba did the masonry work. The carpenters were paid $2.50 per person per day. The total cost of the barn was $1,800. It was designed from the nearby Frank Pepper round barn. While some speculate that round barns were built because they were expected to withstand winds better than rectangular barns, Mr. Lisker thinks that his grandfather chose to build a round barn because of the ease of feeding cattle in a circular structure.

The current owner, Edward Lisker, describes the materials used by his father and grandfather in building this 60 foot diameter barn: "The basement was built out of large sand rock which was hauled from another farm on a steel wheeled wagon pulled by horses. All of the lumber was from the farm. Everything was done by hand: the handling of the rock and the logs cut with handsaws. My uncle made a special handsaw to cut the lumber. The silo was built from two layers of 2x4's with paper between the layers. The metal exterior is original."

Over the years, the Lisker family has made several changes in the barn. Electricity was one of the first modern features to be added; though a gas engine operated the first milkers. Ed Lisker writes: "When we started farming in 1947, we changed the milker and in a few years we installed a barn cleaner. Within the next 20 years, we quit using the silo inside of the barn and built three other silos. We also removed the stalls used for calves and added more stanchions so we could milk 40 cows instead of 30." His wife, Mildred, adds: "It was handy to feed silage from the middle of the barn but it was a little unhandy to fill.

The Liskers also found out that another problem for owners of round barns is that "everything in the barns always costs more because it was in a circle." For example, the barn cleaner and the milk pipeline were more expensive that those fitted for rectangular barns. For the pipeline several sections of stainless steel pipe were sent to Chicago where a manufacturer provided the desired curve.

Back to the main tour page or continue the tour:

- 1. Viroqua –Hwy.56 east to Defreese St./Upper Maple Dale Rd.

North side of the road.

- 2. Bloomingdale – Cty.S to Pa’s Rd. South side of road.

- 3. Dell – Cty.P just east of Dell. North side of the road.

- 4. Ontario (west) –Hwy.131 to Lower Ridge Rd.

or cut across on Dobbs Valley Rd. to Lower Ridge Rd. North side of Lower Ridge Rd.

- 6. Mt. Tabor (west) – From the north: Cty.F to Harris Rd. From the south: Hwy.33 to Harris Rd. West side of the road.

- 7. Mt. Tabor (north) – From Cty.F north on Cty. V. East side of the road.

- 8. Mt. Tabor (south) – From Cty.F south on Cty. V. East side of the road.

- 9. Trippville – Cty.F to Dank Rd. At the end of Dank Rd.

MENU

MENU